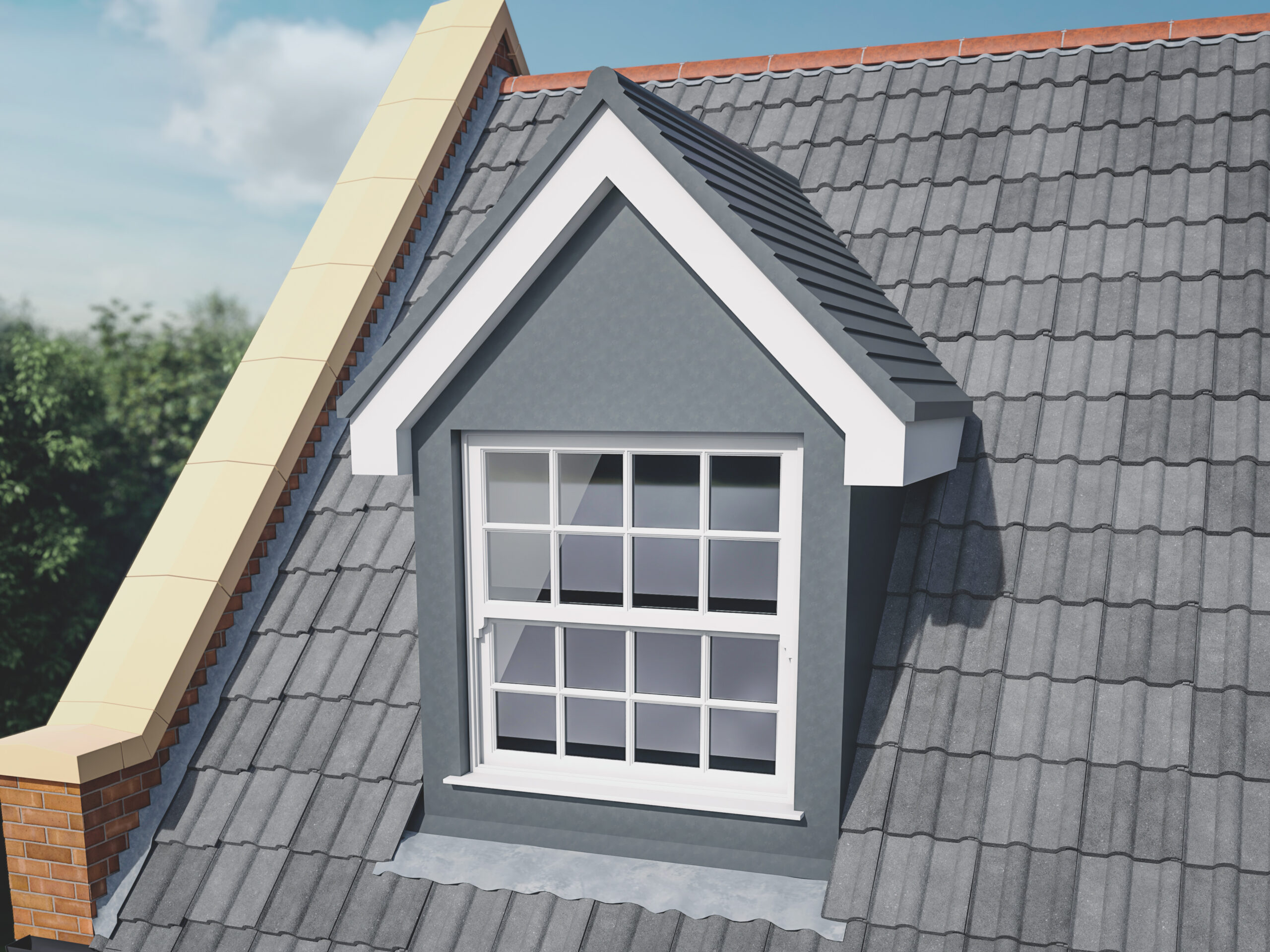

- Wide product range

- Free site delivery*

- BBA Certified

- Onsite support team

Your Specialists in GRP Products

- Comprehensive GRP Products Solutions

- Dedicated Support for GRP Products

- Nationwide GRP Products Delivery

- Extensive GRP Products Portfolio

- Quality-Assured GRP Products

- High-Volume GRP Products Manufacturing

Adapting GRP Products to New Building Regulations

As an industry leader in GRP building components, we take pride in being at the forefront of addressing the recent update to Part L of the Building Regulations. These updated regulations, which came into effect in June 2023, place a strong emphasis on enhancing thermal efficiency and minimising CO2 emissions.

Responding to Part L Building Regulations, Stormking’s GRP Products now offer enhanced insulation, aligning with eco-friendly construction standards and ensuring our GRP Products lead in thermal efficiency.

Explore Our BBA-Accredited GRP Products

SmartStack Stone Effect GRP Chimney Ranges

Empowering Construction with GRP Solutions

- Utilising advanced techniques for premium GRP components.

- Tailored manufacturing to meet specific specifications for GRP products.

- Access our in-house design and technical teams for support with your GRP projects.

- Commitment to eco-friendly practices with FSC/PEFC certified timber for GRP products.

- Proudly designing and manufacturing all our GRP components within the UK.

Drawing on over 30 years of experience in GRP product production, Stormking stands as your premier choice for prefabricated GRP solutions. Our process simplifies specifying Stormking products, thanks to the expertise of our in-house Design and Technical Teams ready to address any project inquiries. Embrace the flexibility and innovation offered by GRP, backed by our cutting-edge manufacturing and design technology, to bring your vision to life with unparalleled freedom and precision.

Accreditations

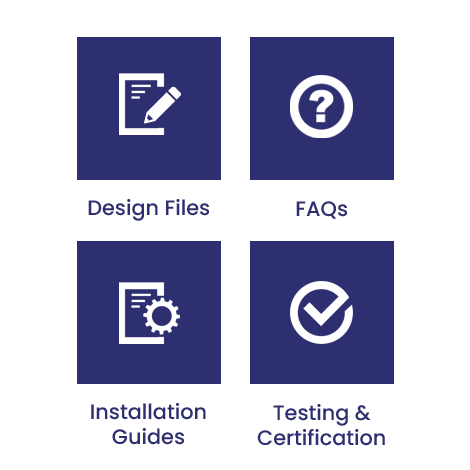

Visit Our Tech Hub

Stormking’s Technical Hub contains drawing files and technical data for the Stormking range of products.

All Stormking products have been designed and engineered by our in-house team of technical experts, drawing from over three decades of experience in supplying the building sector.

Who we work with